What do microchips, stone-washed jeans, 3D printing, paint removal, and meat products have in common? All rely on laser marking, which uses a focused beam of light to ‘mark’ a surface with symbols or patterns. It’s an intricate process controlled by a system of highly specialized software and hardware components.

Building such a system demands considerable expertise. A business must employ people who are capable of developing complex software and firmware alongside drivers, a programming interface, and an intuitive GUI. They also need someone with experience designing and developing hardware.

As if all that isn’t challenging enough, each one of these people also needs a detailed understanding of laser marking technology and the industries in which it is used. This includes knowledge of different types and models of lasers, the benefits and drawbacks of different scan heads (a series of small mirrors that direct a laser’s beam), and how every component in a laser marking system fits together.

It isn’t quite rocket science, but it is close. Given that, it isn’t surprising that the industrial laser marking market has, for much of its history, been dominated by three well-established companies. It simply isn’t feasible for a startup to overcome the high barriers to entry.

Or so everyone thought. Enter HALaser with open-source BeagleBone hardware.

Laser Precision

A laser system typically consists of three fundamental building blocks.

- Control/Marking Software. Allows the user to interact with the system. This may include uploading designs, integrating with smart manufacturing technology, or inputting complex commands via a programming interface. In some systems, the marking software and user interface are separate components.

- Scanner Controller Card. Manages the position of the laser based on input from the system’s marking software via a scan head. It also receives and pre-processes marking data.

- Laser. Self-explanatory.

The controller card updates the position of the scan head’s mirrors at least 100,000 times per second. In parallel, the card also controls the laser, turning it on or off, setting its power and intensity, and changing its modulation frequency. Because the mirrors reposition so quickly, the laser must be switched with microsecond precision.

“Any delay or interruption in a laser system, no matter how small, can derail an entire job,” explains Michael Pfeiffer-Härtl, Owner and Founder of HALaser Systems. “Control of the laser must be perfectly synchronized with the movements and positions of the scan head’s mirror.

“Achieving this level of coordinated precision is extremely challenging and requires not only sophisticated firmware but also powerful, specialized hardware,” he adds.

Breaking Into a Closed Market

“We did things the hard way,” reflects Pfeiffer-Härtl. “We started our business in a market where there were already several well-established companies providing similar products to customers who were quite familiar with their systems. We knew that if we were to break into this market, we’d need to offer some excellent unique selling points – something to justify the fact that a prospective customer would have to start over with a new system.”

Initially, HALaser accomplished this on the software side.

To date, HALaser is the only vendor that provides laser marketing software for both Windows and Linux. During initial development, the company also adhered to extremely strict design rules. This resulted in an end product with modular, maintainable, and intuitive software architecture, thereby streamlining all future development efforts.

“When we first created our software, the rules we adopted made things more complex and time-consuming,” Pfeiffer-Härtl explains. “However, it also made all future development cycles much shorter. This has allowed us to release new features and adapt our software to new use cases very quickly.

“When customers ask for special functions that don’t yet exist, we are available and willing to discuss how we might implement them in our systems,” he adds.

During this time, HALaser used hardware from a third-party vendor. But this was only ever a temporary solution.

“Following the same path as competitors and using expensive, complicated-to-program FPGA devices was never an option for us,” continues Pfeiffer-Härtl. “From the moment we were established, we began searching for something better. Our search came to an end when we discovered BeagleBone Black.”

Priced to Impress

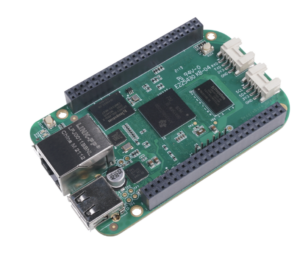

Created by the BeagleBoard.org Foundation, BeagleBone Black is an open-source hardware platform designed with cost-effectiveness and expandability in mind.

BeagleBone is impressively powerful, with a resolution time of 0.5 µs. The unit supports incredibly accurate calculations—32-bit floating and 26-bit fixed-point—while also consuming only a few watts under a full load courtesy the onboard Texas Instruments Sitara AM3358 SoC (predecessor of the new TI Sitara AM625 processors available on next-generation platforms like BeaglePlay).

Note also that HALaser is leveraging the full capabilities of the SoC, configuring two Programmable Real-Time Units (PRUs) to work in parallel with the AM3358’s main core (Figure 3). Designed for deterministic control applications, the specialized PRU hardware accelerators allow HALaser to achieve greater I/O throughput and reduced latency.

Contrast this with HALaser’s competitors in the laser marking industry, whose controllers have a 20-bit maximum, a 10 µs resolution time, and undisclosed power consumption.

“We started with BeagleBone Black because of its performance and significant IO,” says Pfeiffer-Härtl. “We recognized almost immediately that it was the missing piece in our growth strategy – the advantage that would allow us to outperform our competitors.”

HALaser’s first step was to develop its own software on the BeagleBone platform. Today’s BeagleBoard.org platforms like BeaglePlay and BeagleConnect Freedom address use cases like this through support for the Zephyr RTOS, which is based on CMake so it can be built on Linux, Windows, or macOS and still deliver pre-emption and time slicing in a minimum memory footprint of around just 4 kB. But Zephyr did not exist when HALaser began its product development, and the BeagleBone Black’s base Linux OS was unable to support the application’s extreme timing requirements.

Ultimately, the company ended up with a bare-metal implementation of its firmware, which loads in a fraction of a second and fits into a single file under 400 kilobytes in size. With the firmware complete, HALaser integrated the BeagleBone Black into its systems. Each unit is connected to the laser’s control interface, scan head, and a converter card that allows it to send and receive high-frequency differential and analog voltage signals with configurable pulse width.

Arguably the most impressive thing about BeagleBone Black is that it achieves all of this at an exponentially lower price point than comparable systems.

“Though they aren’t exclusively the reason for our lower cost, BeagleBone is a beast in function but not in price,” Pfeiffer-Härtl notes. “We sell our controller cards for up to 80% lower than competitors while also outperforming many of their cards.”

Working with BeagleBone has also allowed HALaser to design its laser marking systems with customization in mind. The company’s clients- typically machine-building organizations and some shops and universities—can easily tweak any of HALaser’s products to their own unique use case. In that regard, they have a few different options.

First, each scanner controller card comes with a free-to-use programming interface so the user can adapt any application for which one could use a laser scanner system, even ones HALaser has not itself considered. Scanner controller cards also come with an unlimited license for HALaser’s standalone laser marking software, BeamConstruct.

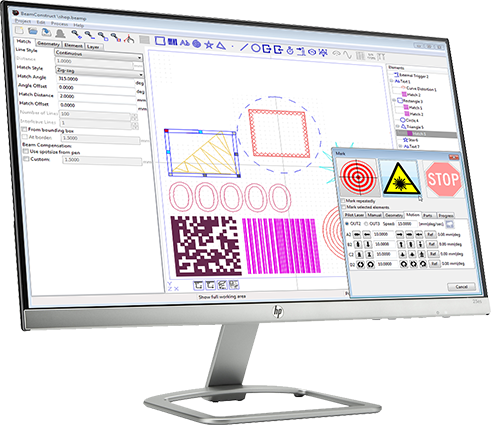

Described by Pfeiffer-Härtl as a “Swiss Army Knife application for laser marking,” BeamConstruct provides a range of predefined functions via an accessible GUI.

The software can even be installed directly onto a machine for control of the production process. It also has its own programming and remote control interface, enabling easy integration into existing infrastructure. Pfeiffer-Härtl notes that BeamConstruct is already being used in automated environments such as smart factories.

Going Green

Shortly after releasing its first controller card and stepper motor controller with BeagleBone Black, HALaser began developing its second scanner card model, the E1803D all-in-one controller. It was during the development process that the company discovered BeagleBone Green, a mod of BeagleBone Black developed by Seeed Studio intended to make the hardware more suitable for commercial deployment. The company decided to switch over, working with Seeed during the transition.

“We originally chose BeagleBone Black due to its enormous computing power and its incredible amount of hardware interfaces,” Pfeiffer-Härtl recalls. “BeagleBone Green had the same core features and I/O but was a much better fit for our hardware and didn’t come with any superfluous features such as an HDMI interface or DC power jack.

“Switching over allowed us to reduce our power consumption even further,” he added.

HALaser’s most recent product, the E1702D slim scanner controller, is also built on BeagleBone Green.

Breaking the Barrier to Entry

HALaser originally started using BeagleBone Black because of its performance, significant IO, and cost, and evolved to BeagleBone Green through subsequent developments.

Through BeagleBone’s lower price point and superior performance, HALaser was able to enter a closed market and grow organically into a leading provider of laser marking solutions. That said, the company’s success wouldn’t have been possible without its own experienced team.

“Although we initially worked with some third parties, we made sure to develop the necessary in-house knowledge and competencies over time,” says Pfeiffer-Härtl. “The only thing we outsource is testing and quality control. They require a completely different skillset, and there are companies that are far better at them than we are.”

For years, the laser marking industry was dominated by a small group of companies, owing to its cost and complexity. Many simply assumed that the market would remain as such indefinitely and that the barrier to entry was simply too high. Working with BeagleBone, HALaser proved otherwise – it proved that success requires neither deep pockets nor a big name.

All you need is passion, skill, and an excellent product.

“Thanks to BeagleBone’s capabilities, we were able to break into a more-or-less closed market and establish our company as a worldwide player in the laser marking business,” concludes Pfeiffer-Härtl. “We owe BeagleBone Green for our enormous growth, which was all done without venture capital investment.”