By Natalie Nelms

Standing in line for coffee, a commercial break, boiling water all things that only take a matter of minutes. What if building circuit boards were that easy and time efficient? At New York startup company BotFactory, devices print and assemble electronic circuit boards from your desktop in a matter of minutes. Creating electronic devices has never been easier.

While attending the NYU Polytechnic School of Engineering, BotFactory co-founders, Carlos Ospina and Nicolas Vansnick, were presented with the challenge to design, assemble and test a basic EEG system in their bio-electronics class. While the design of the EEG probes on paper and then on a CAD program took a big part of the semester, what was later revealed as the most critical part of the assignment was the circuit fabrication itself. Out of the eight teams, only one managed to finish on time for the end of the semester. The reason why? It took PCB manufacturers nearly ten days to fabricate and ship all the boards. If only one mistake was made in the design, the team had to send their design for fabrication again ensuring a missed deadline.

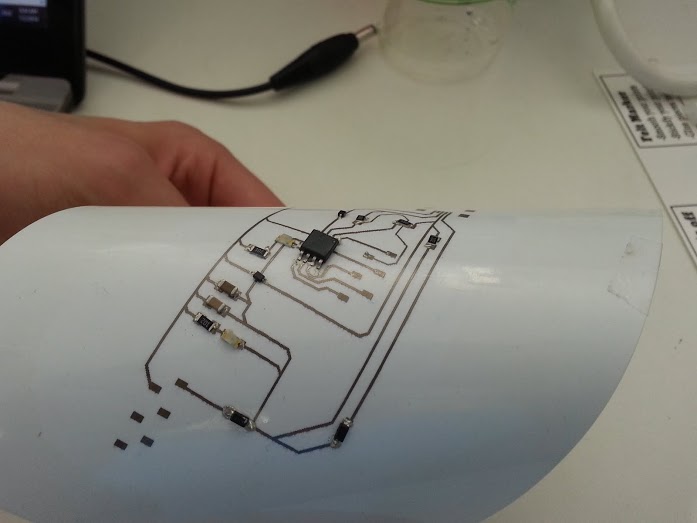

Realizing they had worked on similar time sensitive projects previously, Carlos and Nicolas turned to NYU-Poly professor Michael Knox to create a 3D printer capable of printing circuit boards. After hours of brainstorming on the concept, the pair found their third co-founder and Squink. Squink is a desktop electronic circuit printer and assembler that allows you to upload your design files and create circuit boards in less than thirty minutes for only five dollars.

An intuitive user interface walks you through a three-step process. First, conductive ink is applied onto a substrate, such as photo-paper or glass. Second, conductive glue dots are dropped where part pins will be placed. Finally, Squink picks up the parts from a tray, rotates them and places them on the glue dots to complete the circuits. The Squink printer is run through a web interface, which means you dont have to download any software.

The printer consists of a Sitara-processor-powered BeagleBone Black, 3D-axis frame, custom made board to drive inkjet and five motors, custom made plastic parts for different heads, a camera to run computer vision algorithms and several different softwares.

We choose the BeagleBone Black because we needed a bigger number of IO’s than usually available on other development boards, said Nicolas. The PRU was a very attractive feature to drive our motors efficiently, since we had some problems with our previous development board. We also wanted to use an OS and a multi-platform language, and the price was too hard to beat for the specs it offers!

Can’t keep the printer right next to your computer? Not a problem!

Squink lets you connect through a USB cable, an Ethernet cable, or a wireless adapter. The choice is yours.

Building a circuit board is never without its challenges. The physical

tolerance of parts gave the team trouble during the pick and place process.

Additionally, it took them a while to get a reliable printing head.

The team credits their third-place win and current success to each

individuals perseverance and a desire to prove doubters and non-believers

wrong. We would not be where we are now without the support from

the hardware and maker community in New York City, said the team.

It takes real believers to move mountains.

For more information about Squink or to help support the project,

check out their Kickstarter campaign

and website. Additionally,

you can follow their journey on

Facebook and Twitter.

Video credit: BotFactory Squink

Want to chat with us about this project? Tweet us at @BeagleBoardorg!