By Natalie Nelms

Computer numerical control (CNC) milling machines

have been around for decades. Most are industrial-sized,

and are used create everything from the shaped trim on

a house to the mechanical components of a space shuttle.

Over the last decade, a large do-it-yourself community has

emerged giving a new market to CNC milling machines as personal,

rather than solely industrial applications.

Matt, Michelle, Gary, Duane and Bannor from

Pocket NC have

always been tinkerers and enjoy pursuing projects from their

homes. After searching long and hard for a personal desktop mill,

Matt and his team turned to the Sitara-processor-based

BeagleBone Black to design and build a milling machine for themselves. Thus,

the Pocket NC P5 was born!

We saw an amazing opportunity for creativity that could open up

if we had the ability to make real parts for projects and

prototyping from our house, said Matt, the inventor captain

from Pocket NC. Three and a half years ago we embarked on the

journey to bring a sophisticated milling machine to the masses.

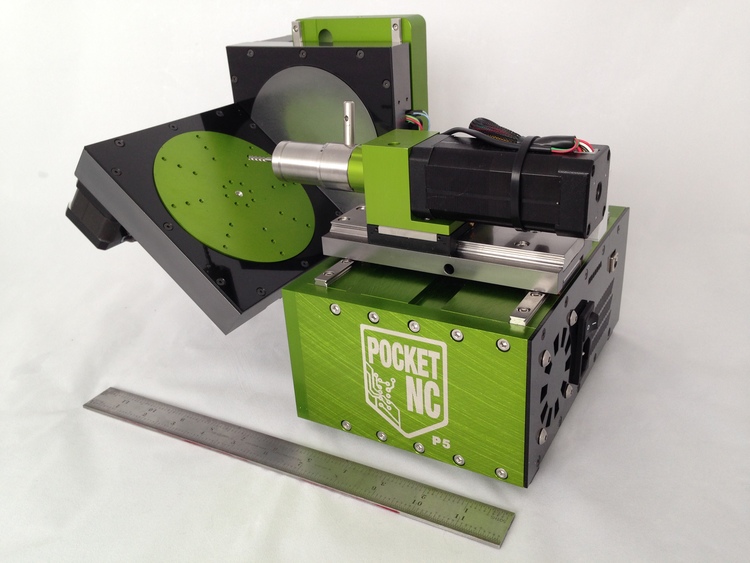

The Pocket NC P5s subtractive manufacturing process starts with

a solid piece of material and carves out the desired part according

to computer generated tool paths. Compared to 3D printing, milling

offers a much wider variety of possible materials to use

(including metals and wood), which produces stronger finished parts.

Pocket NC P5 is driven by the LinuxCNC distribution Machine Kit

running on a BeagleBone Black. The 5-axis machine utilizes precision

linear and rotary bearings, stepper motors and an NSK spindle with

quick change capabilities and brushless servo direct drive.

We chose the BeagleBone Black for its compact size and functionality,

Matt said. Its powerful enough to drive all five axes of our machine;

and it offers many GPIO pins and fast PRU pins. The features on the

board gave us hope that we could bring desktop machining into

the 21st century.

Although the teams strengths are predominantly mechanical skills,

they found engineers and hobbyists to assist with the project in the

electronics and software areas. The Pocket NC P5 project is fully

funded by the team, so challenges arose when looking for people to

contribute without an immediate payout. Finding the right people who

are passionate about the project ruled out the financial hardships

that came with the project. Funding the project themselves, the team

learned how to be creative in finding ways to prototype their machines.

The team took sixth months to develop the design of a 3-axis mill

but quickly realized many people would be more interested in a 5-axis

machine. After building and learning from three prototypes, they

built a fourth prototype that they took to World Maker Faire New

York in 2013. Today, the team is in the process of building and

testing five Beta machines before taking the product to market.

We want to continue developing our machine to bring down the cost,

while also adding more features to it, Matt said. We will either be

working on that, or developing a perpetual motion machine. We have

learned a lot through the process and are always thankful for the

encouragement and support we receive from the community.

If you’d like to learn more about the Pocket NC P5, feel free to

visit www.pocketnc.com or check it out on

Facebook,

Twitter

and Instagram.

Want to chat with us about this project? Tweet us at @BeagleBoardorg!