For decades, direct digital controllers – edge processors running on low-bandwidth serial networks – have been the standard for managing commercial building systems. In recent years, however, these devices have started showing their age. There is now mounting pressure for building owners and managers to embrace technologies such as the Internet of Things.

This new approach brings a lot to the table. Between reduced energy usage, analytics capabilities, lower operational costs, and more efficient maintenance, a smart building automation system (BAS) can potentially save an organization tens of thousands of dollars. Implementing these systems is often easier said than done, however.

Replacing conventional control devices is only the first step. The next is integration. Unfortunately, even newer solutions aren’t always designed for interoperability, instead functioning as closed systems with proprietary hardware and software.

As if that’s not challenging enough, many BAS devices require specialized professionals to manage installation, software updates, and maintenance. The monitors and sensors in a BAS also generate a downright overwhelming volume of data, which must then be orchestrated. Finally, there’s the matter of cybersecurity – every BAS device is a potential target for threat actors.

Factoring in all of the above, it’s little surprise that there are so few companies in the building automation space. The broad expertise and capital required to tackle the upfront cost and complexity are beyond most organizations. Alper Üzmezler intends to change that through Project Sandstar.

In Search of Smarter Automation

A first-generation American, Üzmezler emigrated to the United States in 2000. Shortly after his arrival, he began designing and developing visual building automation software for Allerton. From there, Üzmezler eventually moved to a position at Honeywell before becoming Managing Partner at BAS Services & Graphics (BASSG).

In 2005, Honeywell acquired Tridium, which Üzmezler describes as the world’s de facto building automation company. This acquisition would indirectly lead to Üzmezler’s first experience with BeagleBone in 2008. But explaining exactly how that happened requires a bit of backstory.

“Prior to Tridium, integration between different systems and protocols was extremely difficult,” Üzmezler recalls. “It solved that problem thanks in no small part to Brian Frank, chief architect of the Niagara framework. From his work on Niagara, Frank also developed the Sedona framework.”

Shortly after Tridium’s acquisition, Frank left to open another company called SkyFoundry.” SkyFoundry’s flagship product, SkySpark, proved to be a game-changer – and not just for Üzmezler.

Reaching for the Sky

In 2014, UC Davis engaged Tridium to help it incorporate a fault detection and diagnostics system into two on-campus buildings as part of its sustainability efforts. Based on Üzmezler’s guidance, Tridium developed a Sedona controller for the project. The company then deployed its new controller with a BACnet protocol on BeagleBone, at which point Üzmezler installed a pared-down version of SkySpark into the stack.

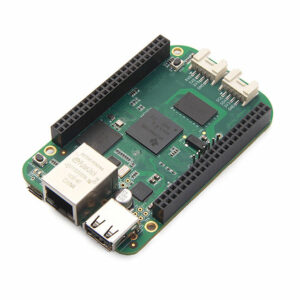

“We chose BeagleBone over similar hardware like Raspberry Pi because of its open-source ethernet controller and additional I/O,” Üzmezler recalls. “The hardware could simply do more – and at a lower cost.”

In its first year of deployment, the completed system – which cost only $5,000 to develop – helped UC Davis identify roughly $40,000 worth of leaks via a connected flow meter. The university could additionally save up to $1 million annually by implementing the technology across its entire campus.

Though the project was immensely successful, for Üzmezler, it was only the beginning. He knew the potential applications of a fully open-stack building automation system went far beyond UC Davis’s use case. Recognizing an opportunity, he immediately set to work on a new project.

“I reached out to Solidyne, one of our partners on the UC Davis project, to retrieve the source code,” continues Üzmezler. “I wanted to use it to create something truly revolutionary.”

And that’s exactly what he did. Following five long years of research and development between BASSG and the newly-founded Anka Labs, Project Sandstar was born.

From Sand to Stars

Project Sandstar is the first entity of its kind – a fully open-source, hardware-agnostic building automation system. It’s built from the following components:

- Sandstar. A fully open-source, hardware-agnostic controls engine with a built-in driver abstraction layer to enable seamless connectivity with different hardware devices.

- Project Haystack. An open-source semantic data model designed to streamline and standardize the data generated from IoT devices. Haystack ensures data is interoperable across devices and systems.

- Sedona. An open-source building automation framework based on Niagara and intended for resource-limited devices. Sedona leverages a declarative programming language that’s easy to understand and designed specifically for describing control logic.

- SkySpark/Analytik. A cutting-edge analytics platform that orchestrates and analyzes data generated by smart devices and equipment systems.

- ArcBeam. A secure WebSocket communication platform that enables both clustered haystack communication and safe data transfers.

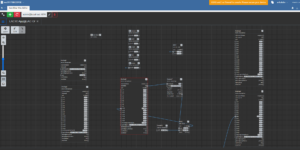

- Visualytik. A powerful and intuitive data visualization tool developed by Anka Labs with the capacity to create and display dashboards through flow-based programming.

- Mobilytik. A companion to Visualytik that enables Haystack data visualization via a smartphone app.

- BeagleBone Green(BBG). An open-source, cost-effective and expandible hardware platform, BBG is a differentiated version of BeagleBone Black(BBB) developed in partnership with SeeedStudio. It removes several of BBB’s extraneous features to offer the same performance with reduced power consumption.

New devices and systems are integrated into Project Sandstar using Sedona via the engine’s driver abstraction layer – an entirely plug-and-play process. The data they generate is automatically orchestrated by Skyspark, at which point it can be accessed and visualized through Visualytik dashboards. The platform also allows a user to drill down to specific devices or data types, such as historic zone temperatures for a particular cluster or the real-time operational status of an individual controller.

One can also use Project Sandstar to transmit commands directly to any connected devices or systems. Lastly, BBG provides a high-performance, low cost and reliable hardware foundation for project SandStar, with excellent speed even when managing large tasks such as real-time data replication.

No More Proprietary Cages

One of the most significant deployments of Project Sandstar occurred in 2019. Working with systems integration partner SysConverge, BASSG deployed a distributed analytics solution on thirty BeagleBone Greens at a major Canadian government facility. It was actually SysConverge that initially sought out Üzmezler and his team due to frustration with their existing BAS.

The facility in which the deployment eventually occurred featured a series of relays for the management of both temperature and air quality. These devices suffered frequent failures – likely due to the extreme variance in temperature between winter and summer, with the latter dropping as low as -40 ºC and the former reaching as high as 50 ºC.

Unfortunately, identifying and troubleshooting these failures proved incredibly challenging with the facility’s current BAS solution.

“Prior to the BASSG deployment, we worked with solutions from vendors like Johnson Controls,” explains Ian Ho, Partner and Senior Consultant at SysConverge. “This not only required manual data analysis of CSV files but also forced us to use proprietary and expensive solutions ecosystems. We joined Project SkySpark because we knew there had to be a better way of doing things – that was how we met Alper.”

Ho and his colleagues were immediately intrigued by Project Sandstar. It not only cost less than half the price of SysConverge’s existing implementation but was also simpler to both install and operate. New devices could be deployed through a simple plug-and-play process, and SysConverge could troubleshoot issues internally rather than having to go through a back-and-forth with a vendor every time something went wrong.

What’s more, Ho notes that BeagleBone Green had a much larger mean time between failures compared to their previous system. This prompted SysConverge to commit to using BeagleBone as a replacement platform wherever possible, even once the deployment concluded. With that said, the companies did identify a few potential areas of improvement for SandStar, such as read-only memory and a more robust capacitor for industrial control use cases.

For BASSG, insights gained during the deployment allowed it to springboard into another project during the pandemic. After spending some time assessing COVID-19 and how air quality impacts its virality, the company developed a sensor analytics system to help hospitals and other spaces track metrics such as humidity and particulate matter. The end goal of the project was simple – to help mitigate the spread of infections through better air quality monitoring.

Embracing A More Intelligent Future

If it wasn’t already obvious, BASSG’s attitude towards Project Sandstar is one of continuous improvement. Üzmezler is constantly on the lookout for innovations and ideas. Alongside the insights gained through his work with SysConverge, he’s zeroed in on a few steps that he feels will even further improve the smart BAS.

“With machine learning, our system could dynamically predict usage and environmental changes and adjust edge devices accordingly,” Üzmezler explains. “LoRaWAN connectivity, meanwhile, would allow us to even further optimize performance and power usage. We’re also planning to eventually start deploying projects on BeagleV Fire.”

“I’m really hopeful for the future,” he concludes. “With BeagleV Fire, we could potentially quadruple the speed of our entire system, generating more value for less in future building automation deployments.