By Tara Stratton

Addie Wagenknecht and Stefan Hachenberger, co-founders of NORDT

Labs, have many secret talents. Addie can bake some mean chocolate

chip cookies at 15,000+ feet in high winds on a mountain, and she

can open a beer bottle with just about anything (like a lighter)

thanks to Becky Stern. Stefan, on the other hand, makes the best

kiserschmann in Austria, according to Addie. But their most

recent projectthe Lasersaurshows their best talent yet.

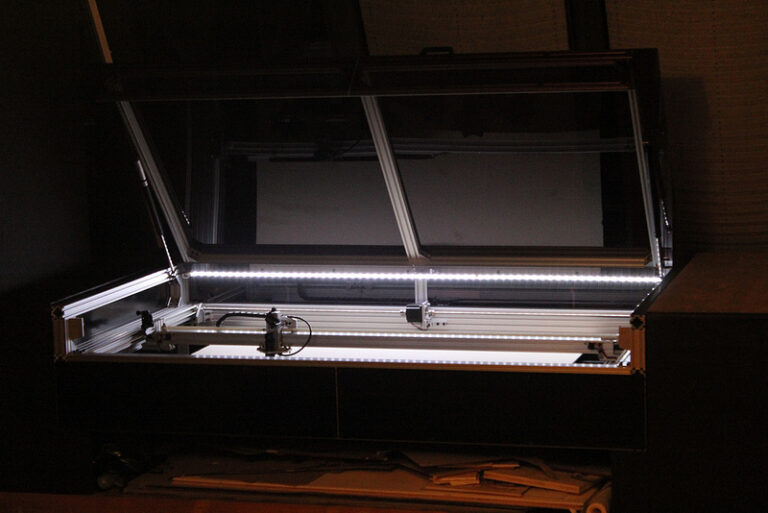

The Lasersaur is an open source laser cutter. With CAD drawings,

circuit schematics, software and a bill of materials available from

NORTD Labs, end users can build these laser cutters themselves. The

Lasersaur was designed to fill the needs of makers, artists and

scientists who want a safe and highly capable machine.

Image credit: NORDT Labs

When Addie and Stefan designed the Lasersaur, they werent

interested in building the cheapest machine. They were interested

in building a platform that is sourceable worldwide, simple to

build, reproduce, duplicate and understand, dependable after

hundreds of hours of use, and safe. They want the end users to

truly own it and have access to all the designs that went into it.

We had spent thousands of hours on other peoples laser cutters

while in graduate school. We depended on the systems, yet they were

expensive and frustrating to use, said Addie. The software was

often horrible. We would have to run some obscure machine, running

CorelDrAW, and transfer everything from our OSX or Ubuntu systems to

do it. We felt like it could be done better, and for a lot less than

what it would cost to buy ready-made.

As a result of this experience, Addie and Stefan have written the

Lasersaurs open-source software and plug-ins from the ground up,

and according to Addie, they will do things you have never seen

beforeopen-source software or not. It is locally hosted and can

run off of any web browser, which means you don’t have to install

additional software or extensions to get it to cut. It’s plug and

play.

Addie and Stefan havent fully opened the source for the Lasersaur

yet, but hacker spaces in Philadelphia, Dublin and Tokyo; labs at

Carnegie Mellon, NYU and the University of São Paulo; and many

individuals have already built their own Lasersaur.

The Lasersaur is based on BeagleBone Black, powered by TIs Sitara

AM335x processor. Addie and Stefan chose this computer because they

were interested in continuing to work with and support Linux.

Since Ångström was pre-installed, we were able to continue to use

Ubuntu for the Lasersar. We found BeagleBone Black plays well with

USB peripherals like Wi-Fi dongles. It was rather painless to get

the Lasersaur image configured onto BeagleBone Black, so it felt

like a shoo-in. As a bonus, its globally available, stable, easy

to pick up, learn and hack, and the price is right! said Addie.

Lasersaurs are built to use 40-200 watt carbon dioxide lasers and to

have a bed size of 24 × 48 in (61 × 120 cm). They are comprised of

both stationary and dynamic parks. The primary building blocks of

both the frame and the ganty are T-slot aluminum extrusions bolted

together with M5 bolts and T-slot nuts. The Lasersaur is designed

around extrusions with 20, 40 and 80 mm side lengths. All of the

mount assemblies are built from angle brackets. A few parts are

custom-cut 6 mm acrylic (or more recently, aluminum) pieces. CAD

drawings for the acrylic parts are freely available and can be made

using a laser cutter – and should they fail, they may be replaced

with spare parts made by the Lasersaur itself. Aluminum versions of

those parts may be purchased from the NORTD Labs store, or users can

have them cut somewhere. No proprietary rails and carriage

assemblies are used. The Lasersaur carriages are built from

standard-sized ball bearings (with nylon coating), cap screws and

custom-cut acrylic or metal pieces.

According to Addie, the biggest issue has been funding. At first we

used Kickstarter. At some point far enough into development, we were

able to take fellowships and residencies to further fund the

project and push it forward. We also put our own money and time

into it. At some point, the community support allowed the project

to almost become self-sustained. We hope to get the financial and

social capital to 100% one day. University builds like that of

Carnegie Melon and New York University have been a big help to the

exposure of the project.

For more information about Lasersaur, visit Lasersaur.com.

Addie and Stefan have completed many other successful projects. To

find about more about them, visit the NORTD Labs website.

And definitely stay tuned: theyve been toying with an interesting

idea for an open-source industrial robotic arm!